PCB Gold Fingers, What you should know

You are probably thinking of a sophisticated device that networks with other electronics easily, right? Perhaps a wearable like a watch that interacts with a TV or something much bigger, correct? Maybe I am wrong…

But to most of us, the ease of interconnecting devices (by extension PCBs) is the sure sign of device complexity. That’s why improvements in PCB Gold Fingers are the missing link to future electronics. Gold Fingers are used to enhance inter connectivity of conventional circuit boards to larger PCBs.

Their applications have become increasingly popular in modern PCB manufacturing and PCB assembly projects. They look pretty. But besides their stylish outlook, what more do you need to know about them? What is their relevance? Are there regulations that guide their production and usage? Well, to know more about this exciting field of PCB gold fingers, consider scrolling a little bit through this edition for more answers.

1: Gold Fingers PCBs

1.1 Definition

As outlined before, the term “Gold-finger PCB” is used to refer to gold-plated connectors mounted at the interconnecting edges of a periphery PCB. Other names to call a Gold finger PCB abe re a Gold Connector, Edge Connector, Edge-Board Connector, Connector Finger, Contact Fingers, Gold Taps or Gold Tips.

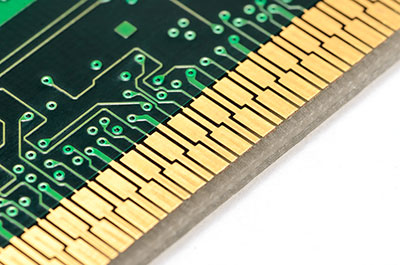

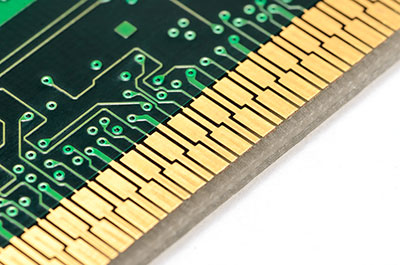

It is possible you too might have interacted with Gold Fingers PCBs in the past. Wait, can you remember interacting with a collection of shiny looking, finger-like projections on the edges of a joining end of a peripheral circuit board? Aha! That’s what I am talking about here. They resemble fingers in the sense that they look thin and elongated at the contact edges of a PCB. Gold Fingers are usually fitted onto the edges of periphery PCBs or prototype boards to enhance connectivity with larger boards.

The edge connectors (i.e., gold fingers) are also plaited with flash gold (hard gold) with a thickness that varies between 3u’ and 50u’ (units in Micro Inches).

1.2 Why Gold Plaiting Is Necessary For Gold Fingers PCB

Primarily, PCB connection points are subject to constant plugging and unplugging owing to their nature of interconnecting PCBs. Hence, without a strong contact edge, they are prone to wear-and-tear that can cause device malfunctioning. The act of plaiting the connectors with other metals (in this case gold) is done to enhance the durability of the edge connectors.

But I am sure you might have wondered: of all metals, why should edge connectors be gold-plated? Isn’t gold too expensive? Couldn’t copper conduct better and be a lot cheaper than Gold? Well, I have an answer: sure, gold plating of gold fingers is expensive, but it is necessary.

Gold was chosen over other metals because so far, gold has proven to have high corrosion resistance, high electrical conductivity (second to copper and silver) and could be alloyed with cobalt or nickel to increase its resistance to wear-and-tear. Earlier experiments that were done to establish the resistance of gold vis-à-vis its resistivity and compared to other popular metals showed that gold had a lower resistance than other metals as shown in Table 1 below.

| Contact Material | Resistivity (Ωcm) | Contact Resistance (mΩ) |

| Pure Gold | 2.4 X 10-8 | 0.8 |

| An alloy of Gold and Cobalt | 2.4 X 10-8 | 2.6 – 2.8 |

| Palladium on Nickel | 1.08 X 10-7 | 3.1 – 5.8 |

| Silver | 1.6 X 10-8 | Non-determined |

Gold is also inert. It does not oxidize or react readily with other metals. This property of gold makes it an ideal choice to make the parts that are prone to be exposed or likely to react with other metals. Even though silver is sometimes useful, it is not recommended for commercial productions as silver is susceptible to sulfide and chloride attacks.

In the current market, there are two main types of gold plating for gold fingers. These are:

1.Electroless Nickel Immersion Gold (ENIG): ENIG is cheaper to acquire and more comfortable to solder than hard gold. However, it is softer, and it cannot withstand constant plugging and unplug without wearing out. It is recommendable for experimentations and prototypes. ENIG is not a good option for commercial usage.

2.Hard plated Gold over Nickel: hard plated gold over nickel is harder and thicker than ENIG. It is most suitable for commercial applications.

In recent applications, a combination of the two types of gold plating techniques is used by most manufacturers in a bid to strike a balance between the efficiency of the electronics and a lower cost of production.

1.3 Chapter Overview

So far, we have learned that gold finger PCBs are gold-woven edge-connectors of periphery PCBs to other PCBs. We have also covered some of the main reasons why gold plaiting is necessary for the connector fingers. In the remaining part of our edition, we are going to lean on how to make gold finger PCBs, their applications and the standards that guide their production. In our next chapter, we will learn to make gold finger PCBs.

2: How Do You Make Gold Finger PCBs?

The essential step in manufacturing gold fingers is the step of gold plating or layering of other metals to PCBs. It required one to have the raw PCB to be plated, a plating bar (image below) and plating specifications.

During the process of PCB manufacturing, gold plating we apply gold after the solder mask process. Most of the times, we perform surface finishing for the rest of the board before gold plating edge contacts. The process described below assumes that you have already acquired a PCB and you only seek to gold-plate its edges to enhance its durability. It involves the following steps:

2.1.1 Steps Involved In Ordinary Gold Plating:

1.First plate between three and six microns of nickel to the edge connector fingers

2.Add between one and two microns solid gold (preferably gold alloyed with some cobalt) layers to the fingers.

3.Bevel the layers carefully to ease insertion of the board to its slot. Most modern designs of PCBs specify beveling level/height. If it is not specified, you can ignore it.

2.2 Making Other Types of Gold Finger PCBs

Because of improvements in Gerber and PCB designing, edge connectors have evolved to have different designs to suit different manufacturing goals. Two of the popular types of PCB gold fingers are the unequally sized edge connectors and the segmented gold fingers.

2.2.1 Unequally Sized Gold Finger PCBs

In some cases, some fingers are intended to be shorter than other fingers within the same PCB. An excellent example of such a PCB is the one used to manufacture traditional memory card-readers (as shown in the image below). The logic in making some fingers shorter than other is that the components linked with the long fingers are must be powered before those connected to the shorter fingers.

2.2.2 Making Segmented Gold Fingers

Segmented gold fingers are used to connect PCBs of most modern hybrid electronics. They are composed of fingers that vary in length and some fingers that are segmented, i.e., disjointed within the same fingers of the same PCB. They are common on water-resistant and rugged electronics.

Steps To Making A Segmented Gold Finger PCB

The production of non-water gold and gold finger plating process is very similar to the standard gold finger production already discussed. However, in this case, one is required to increase precision cleaning the segments.

A summary of the steps is:

Preparation of ENIG/ hard gold → Character Formation on plating bar → Gold Finger Plating → Laser Drilling (the process of segmentation) → Dusting/Cleaning → Sharpening → Electrical testing

Take Note!

1.To ensure that the gold fingers align exactly with their respective edge connector profiles on the joining boards, you will need to rout the vertical edges of the connectors on their first plating run.

2.To maintain the fingers in shape, when doing this process manually, you will need to keep edging out any spillage or excess when adding layers of the finishing material.

2.3 Limitations of Gold Finger PCB Technology

Even though gold finger technology is of great importance, its application is still limited in that:

1.Plated pads must be on the edge of a PCB. Because gold plating involves an electroplating process, there must be a connection linking the plated pads with the connections panel frame.

2.Most plating pads are limited to produce gold fingers that do not stretch over 40mm. In case you might need to have longer gold fingers, the process of manufacturing them might increase.

3.Inner layers of the edge connectors have to be free of copper. Otherwise, the process of beveling the contacts might expose the copper.

4.Except for flexible PCBs, when plating on both sides of a PCB, the minimum separating distance between the upper and the lower layers of the PCB is supposed to be 150mm.

In the remaining chapters, we will now examine the uses of Gold Fingers in the industry as well as their limitations.

3: Applications & Limitations of Gold Finger PCBs

The uses of PCB gold fingers can be divided into both technical (applications on circuits) and industrial/commercial applications. Let us begin with the Technical application of the contact fingers

3.1 Technical Applications Of Gold Finger PCBs

Within the circuit, PCB gold fingers have several uses. Some of the technical applications of the connectors are:

1.They connect a PCB to a power source: one of the primary uses of the contact fingers is to connect a module PCB to a power source on the connecting profile of a larger PCB.

2.They help in the transfer of signals/data: primarily, gold fingers link with the other PCBs to ease the transfer of data and signals between the peripheral PCB and the larger board.

3.They interconnect modules within the same board: traditional electronics used to consist of several robust modules that could not be interconnected easily within the same board. With the aid of flexible PCBs electrical engineers were able to interconnect multiple modules even within the same board.

4.They provide room for future improvements: well, imagine a computer motherboard without ports and expansion slots. How would it look like? How would it function? And would other interested electricians improve it without adding expansion slots or vendor modules? The picture is unimaginable. You would not be able to connect input devices and output devices. Other engineers would not have worked on the improvement of a computer’s keyboard or mouse or VGA card. Simply put: without having gold finger PCBs, machines cannot be improved.

3.2 Commercial applications

In the industry, gold fingers PCBs are used in several areas. Some of the popular applications include:

1.They are used to provide connections for data transfer on network-enabled devices. I.e., we apply Gold fingers in the manufacture of network cards and other additional networking PCB modules.

2.They are used to attach specialty adapters. Edge connectors are used to provide an attachment area for special adapters like Video Graphic Array (VGA) cards and other video cards that are useful in processing images. These additional specialized modules relieve the main board some of the processing that is useful when computing.

3.They are used to connect other devices to the main processing board. Besides the advantage of connecting network modules and specialized adapters, you can also use gold finger PCBs on the connecting edges of peripheral devices that get connected to the main boards. Their application is relevant in the production of devices like Memory card adapters/readers, flash-drives among other devices. These additional devices can help in boosting processing, adding storage memory or powering the main board.

4.They are also used to connect audio adapters to main PCBs.

4:Regulations, Guidelines & Standards

At the moment, the most popular standards that guide the production of PCB gold fingers are those released by The Institute for Interconnecting and Packaging Electronic Circuits. The organisation later transformed into The Association for Connecting Electronics Industries (IPC).

In 2002, IPC released its earliest standards pertaining gold fingers. The IPC-4552 standards of 2002 focused much on guiding the plaiting process of printed circuit boards and PCB finishing. Later, in 2012, they were amended and improved 2012 into the IPC-4556 standards. Then again, of all their releases, the IPC A-600 and IPC-6010 standards of 2015 are still the most popular standards for gold finger manufacturing in the current market. Here is a summary of some of the guidelines to manufacture gold fingers:

1.Visual inspection of contact edges: the edges should be clean and have a smooth texture under simple investigation with the aid of a magnifying lens. They should not possess extraneous plating or “Nickel’s foot.

2.Finishing thickness and size: the layers of the gold fingers should be measured to ensure that the thickness ranges between 3u’ and 50u’ (units in Micro Inches). The standard thickness sizes currently are 0.031’, 0.062’, 0.093’, and 0.125’. For prototypes, we use the lower bound of thickness, and for boards intended for use in areas that require constant plugging and unplugging or excessive force of insertion we use the upper bound. The copper weight for inner finishing layer is 1 oz. while that of an exterior finishing was proposed as 2 oz.

3.Tape testing of contact edges. The most straightforward test suggested to find the adhesiveness of gold fingers is the tape test. The standards recommend a “tape test” to establish the adhesiveness of the plated material on the gold fingers. In carrying out the test, a strip of tape is enforced onto the contact fingers and then removed. Upon removal, a careful examination is done on the tape to find if traces of the plating materials remained on the tape. Any show of the plated material on the tape is an indication of poorly plated contact fingers.

4.Chemical composition: the gold used in electroplating should contain at least 5% – 10% of cobalt. This combination helps to boost the rigidity of the contact edges.

Even though we have given a summary of some of the simplest tests you can carry out to conform to IPC standards, there are still several other guidelines outlined by the standards that guide our production of commercial gold fingers. As professional PCB manufacturers, we are committed to conforming to the latest standards that ensure safety and efficiency of the electronics we offer our clients.

5:Conclusion

Getting to produce standard PCBs that conform to the IPC standards for safety and efficiency is an easy task for a Ourpcb Australia . Precision is paramount, and timeliness in such projects is also critical. Maybe, you have been wondering how you will be able to navigate through the production puzzle.

Please consider checking out our website for more information and offers on PCBs.